In today’s world, the most critical challenges businesses face are adapting to rapidly changing market conditions and changing consumer expectations. The strategy that might have worked for businesses in the last few years may require an overhaul to meet the present requirements.

To meet these ever-changing needs, organizations need flexibility not only from systems but also from processes and people that support the supply chain. However, the issue is that achieving operational potential is a continuously changing target.

Maximizing efficiency with continuous process improvements

No matter how efficient the supply chain is running, finding ways to improve efficiency is something that organizations’ should always be doing.

However, knowing how to optimize and improve your supply chain can be a challenge. This is because it is an ongoing pursuit of moving inventory efficiently to meet the rising demands of your consumer and also manage cost pressures. The organizations that do this effectively don’t just purchase new technologies but look for efficiencies in day-to-day operations.

Organizations need to drive continuous in their operations and supply chain, enabling better order processing, shipping turnaround, reduced costs, increased cash flows, improved stock management, better transparency, and enhanced customer satisfaction. Process improvements become necessary for supply chains and operations to adapt to ongoing changes, technological innovations, increased demands, changing trends, and growing consumer expectations.

The role of continuous process improvement (CPI) in supply chains

Supply chains encompass all operational activities of a business internally, as well as entities and various partners externally. Therefore, supply chains cannot act as a sole entity, they depend on their suppliers upstream and require to continually intensify the level of customer satisfaction downstream.

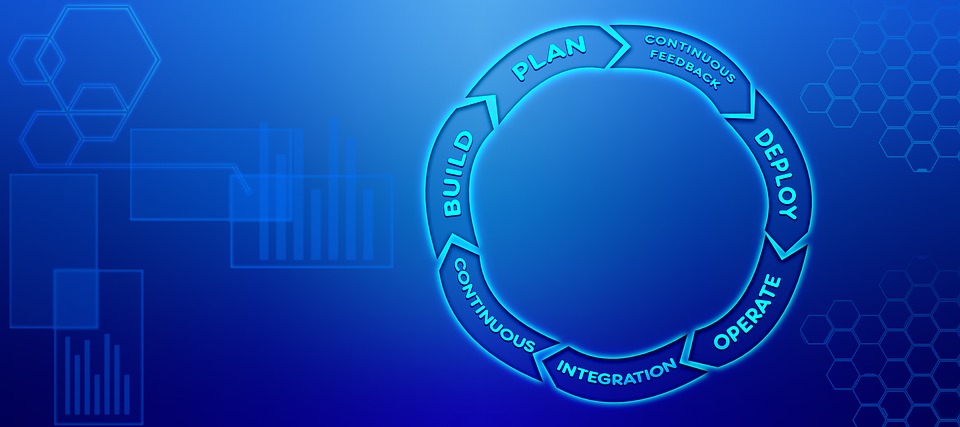

The strategy of CPI is based on three aspects- people, processes, and technology. All three factors should work in tandem for continuous process improvement to be effective in the long term. By aligning people, processes, and technology around a CPI allows for a more effective collaboration between the operational and infrastructure technology teams, and leads to higher productivity, and better deployment of complex supply chain systems.

When organizations ensure that their employees are trained to work within predetermined processes and operational structures and these processes are integrated with technology that streamlines the delivery of preferred topline outcomes- the entire business will benefit from the new levels of productivity and precision.

Continuous process improvement is the key to realizing the supply chain potential

Continuous process improvement is an ongoing project to elevate functions and processes across the supply chain. The process should aim at gradual improvement over time and not ‘one-time’ breakthroughs. The aim should be to reduce inefficiencies in operations at each level. The organizations may be enabled by reducing the time it takes for completion of a procedure, enhancing process efficiency and improving the supply chain quality. Such improvements are based on small tweaks and basic changes and not big breakthroughs or innovations.

CPI is essential for supply chains to cope and adapt to continuous changes, meet higher demands and customer expectations, technological improvements, and deal with uncertain market situations. That said, regular feedback is an integral part of continuous process improvement. It helps in constantly identifying opportunities for further improvement by effectively prioritizing and evaluating the development of designs and concepts.

Conclusion

The bottom line is that ensuring top-line growth is not the only purpose for any organization, but to survive the changing market conditions, and competition in the long run while keeping the customer base satisfied. This can be achieved by managing and controlling the entire supply chain, both internally and externally.

The pre-requisite for supply chain operations is to improve efficiency and effectiveness to the same level by using applicable methods that can facilitate and enhance its implementation. With continuous process improvements, organizations can reduce costs and time, eliminate waste, and ease inventory, increase profits and customer satisfaction levels.

To stay relevant in the constantly evolving market and to maintain market share and competitive advantage, it is important that the organizations endorse extensive use of continuous process improvements throughout the supply chain. This will ensure that their potential framework is adjustable, logical, and resilient to uncertainties, technological innovations, and an increasingly informed customer-base.