Supply Chain executives, leaders, and personnel often find themselves not knowing what inventory they have, where it is, and when it expires. The list of what-ifs can be quite daunting.

Despite the criticality of the answer to these questions, that information is not at the fingertips of executives, leaders and personnel. Needless to say, this should not be the case.

The problem is not exclusive to large pharmaceutical companies with multiple business units and thousands of SKUs; it also shows up in clinical-stage, pre-commercial companies, and companies about to launch products. The challenge manifests very differently of course, if we are talking about a large company vs. a small one, and everything in-between. The drivers differ, and so does the decision-making process.

However, there is hope. This is not a complicated process, but it does require some doggedness and attention. This is best described with an example, so let us look at small biotechs. These teams are mostly under-resourced and uber-busy fighting fires. What falls to the wayside is time to think through where and how to start attacking the problem of building capability, process and tools that are cost-effective, easy to use, and implement. They often give up before simple barriers simply because they don’t have someone to turn-to (e.g., an excel formula, a template for suppliers, emails and quick working sessions to round people up).

4 easy steps to address the problem

Let’s start by breaking down the process:

- Obtain inventory status from each supply chain node at the end of the month

- Aggregate key inventory data elements into a data repository

- Link data repository with a reporting engine (e.g. PowerBI, Tableau, Excel)

- Establish a recurring review and inventory adjustment process

Believe it or not, what will determine the success of this process is step 4, and by the way, that step can be as short as 30 min/month once you get it IN CONTROL. This is absolutely critical because the superb principle at work here is the one popularized by Lean-Six-Sigma about shining a light on something. You shine a light on this, and it will run. The prior 3 steps are also quite easy to run once implemented.

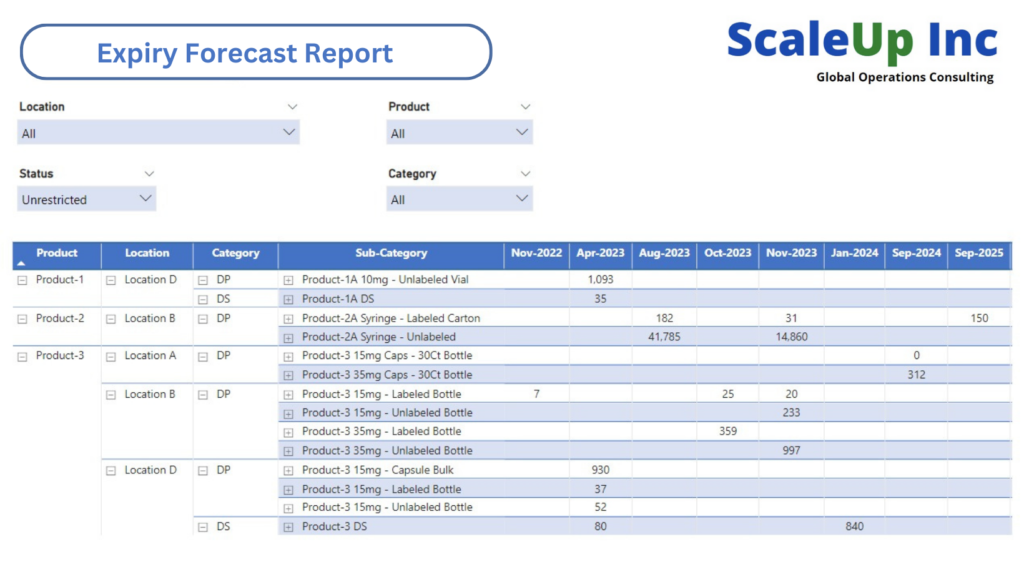

For Step3, the reporting/analytical engine provides robust insights using tactical visualizations and using the right reports makes a world of difference in how pain points are identified and how teams drive decision making.

Here is an example of a simple visualization technique that can substantially impact operational teams and execution.

The above chart, while simple, is a horizon view of expiry across a product portfolio and supply chain nodes. This will enable your personnel enough time to react Vs the alternative of learning expiries within 1-2 months of when it happens. Even small companies can manage and produce this type of insight very easily with expert support. It makes a huge difference to visualize expiries across the horizon Vs present it on a simple list.

What if the inventory review process is not followed?

This process is not running consistently in a large percentage of companies. Given the simplicity of this, why is it not running everywhere? As I said earlier, it is not running consistently because of simple things that teams just can’t get passed. I apologize for repeating myself here, but it can be an excel formula, a template for suppliers, the emails and quick working sessions to round people up.

Another powerful angle to doing something in this area is the support you will get from your Finance department. In my opinion, they should be the first to get in your corner. They will definitely support what you may need to get this process up and running. Their lives will be that much easier and the confidence in where the business stands in this critical dimension will substantially improve.

There are some infamous examples of the staggering cost of failure in this department, and I am sure some of these will resonate, but I can only highlight a few because there are too many scenarios to cover.

- Near-term product expiry at clinics leaving no time to react (e.g., next month)

- Short supply of bulk material to run the next batch and development requirements

- Not enough inventory reserved for a specific batch for a particular study

- Not enough components (e.g., vials, syringes) to perform the last step of the process

The implication of any of these scenarios can derail a program, a launch or commercial operations and ultimately impact patients. The fix is simple and may only require a little nudging from a concerned executive or leader. Get ahead of this one; inventory is like cash…you really don’t want to run out of it.

ScaleUp Inc is an expert in Inventory Management and Analytics and has leveraged the power of Analytics to streamline Inventory Management for multiple large and medium-sized pharmaceutical companies. Please contact us. Let’s partner on a rewarding journey.